Everything You Need To Know About Food-Grade Totes

Posted on January 15, 2021 by xtxwebmaster

In the food processing industry, every stage of production is important. This includes everything from combining the ingredients to storing them to shipping them out. When it comes to high-quality equipment that impacts multiple stages of food processing, more and more companies are turning to food-grade intermediate bulk containers, or IBCs. These versatile units have so much to offer food processing plants. And after learning everything you need to know about food-grade totes, you’ll see why.

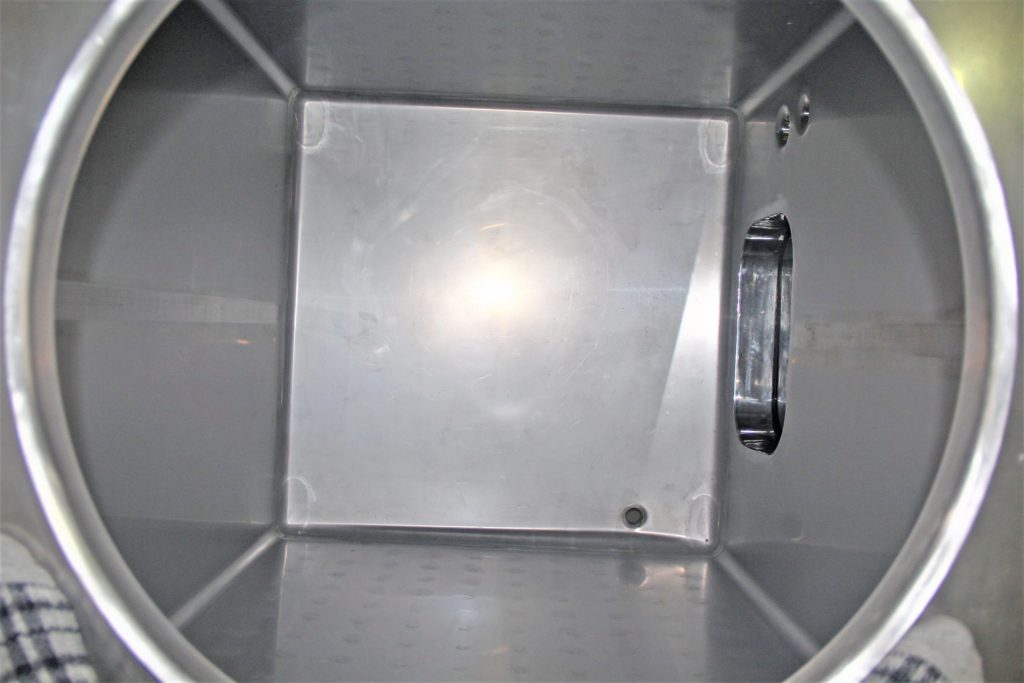

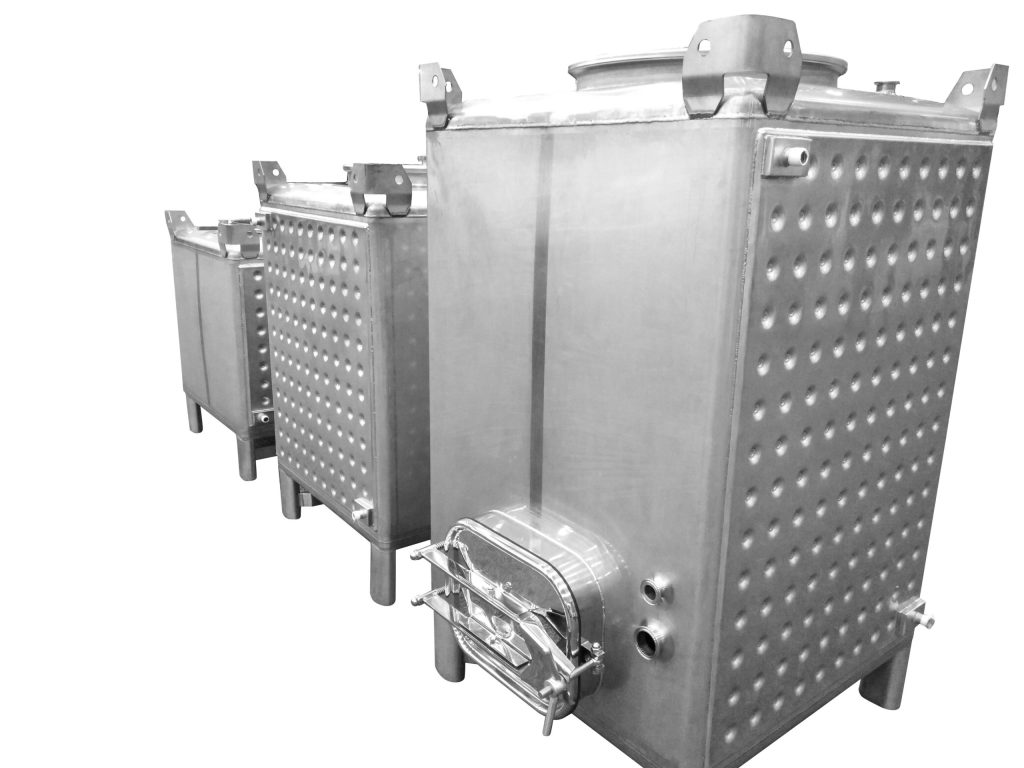

Featured Food Grade IBC

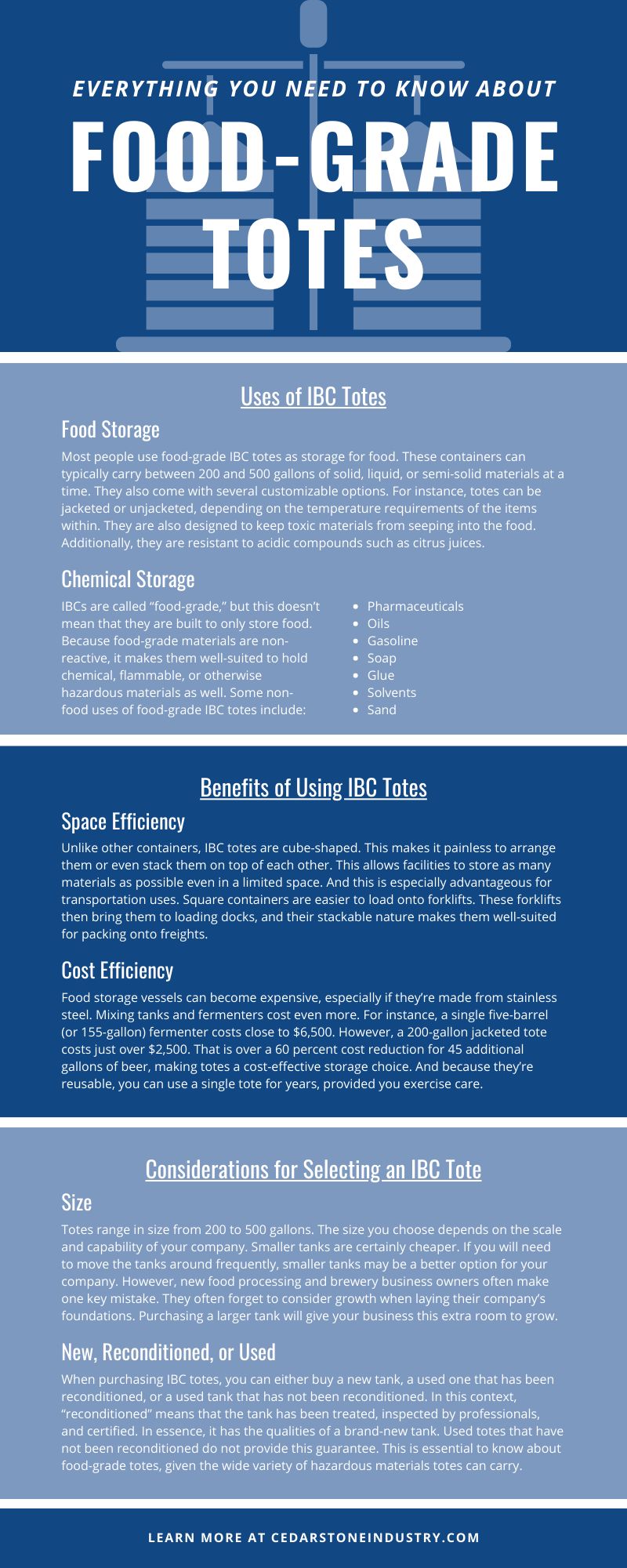

Uses of Food Grade IBC Totes

Food Storage

Most people use food-grade IBC totes as storage for food. These containers can typically carry between 200 and 500 gallons of solid, liquid, or semi-solid materials at a time. They also come with several customizable options. For instance, totes can be jacketed or unjacketed, depending on the temperature requirements of the items within. They are also designed to keep toxic materials from seeping into the food. Additionally, they are resistant to acidic compounds such as citrus juices.

Chemical Storage

IBCs are called “food-grade,” but this doesn’t mean that they are built to only store food. Because food-grade materials are non-reactive, it makes them well-suited to hold chemical, flammable, or otherwise hazardous materials as well. Some non-food uses of food-grade IBC totes include:

- Pharmaceuticals

- Oils

- Gasoline

- Soap

- Glue

- Solvents

- Sand

However, you should note that any tote used to hold a chemical substance should not be used for food, even if the container was washed. You should also clearly label any totes holding hazardous materials whether you keep them in a facility or transport them.

Fermentation

For those in the beer or wine industry, totes are perfect for use in the fermentation process. For an ideal fermentation receptacle, you need a container that you can seal completely. And it should not be made from a material that will react to the acidic contents of fermenting alcohol. Totes feature a lid that locks tightly, and you can easily sanitize the interior and exterior. They can be jacketed, which makes it simple to control their temperature.

Mixing

The simplicity of totes makes them easy to outfit for other purposes; this includes mixing. Using an attachment, you can turn any tote into a mixing tank. Since the totes already feature nozzles, you can make the transition from storage vessel to mixer and back.

Benefits of Using IBC Totes

Space Efficiency

Unlike other containers, IBC totes are cube-shaped. This makes it painless to arrange them or even stack them on top of each other. This allows facilities to store as many materials as possible even in a limited space. And this is especially advantageous for transportation uses. Square containers are easier to load onto forklifts. These forklifts then bring them to loading docks, and their stackable nature makes them well-suited for packing onto freights.

Cost Efficiency

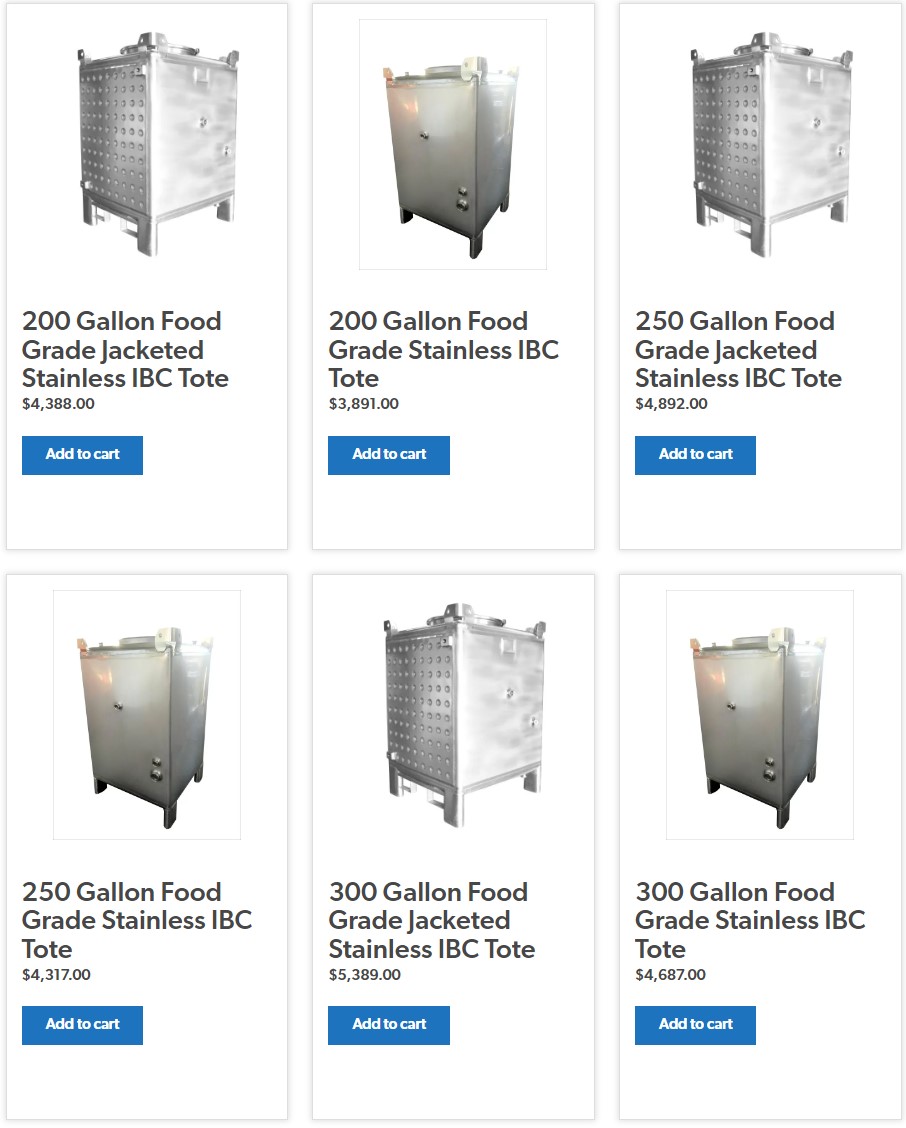

Food storage vessels can become expensive, especially if they’re made from stainless steel. Mixing tanks and fermenters cost even more. For instance, a single five-barrel (or 155-gallon) fermenter costs close to $6,500. However, a 200-gallon jacketed tote costs just over $2,500. That is over a 60 percent cost reduction for 45 additional gallons of beer, making totes a cost-effective storage choice. And because they’re reusable, you can use a single tote for years, provided you exercise care.

Considerations for Selecting an Food Grade IBC Tote

Size

As mentioned, totes range in size from 200 to 500 gallons. The size you choose depends on the scale and capability of your company. Smaller tanks are certainly cheaper. If you will need to move the tanks around frequently, smaller tanks may be a better option for your company. However, new food processing and brewery business owners often make one key mistake. They often forget to consider growth when laying their company’s foundations. Purchasing a larger tank will give your business this extra room to grow.

New, Reconditioned, or Used

When purchasing IBC totes, you can either buy a new tank, a used one that has been reconditioned, or a used tank that has not been reconditioned. In this context, “reconditioned” means that the tank has been treated, inspected by professionals, and certified. In essence, it has the qualities of a brand-new tank. Used totes that have not been reconditioned do not provide this guarantee. This is essential to know about food-grade totes, given the wide variety of hazardous materials totes can carry. If you buy a used tank, even if it’s reconditioned, clean it thoroughly. If you want to avoid this hassle, simply buy a new tote.

Materials

If a tank is marked as “food-grade,” that means its materials will not react to the items placed within. However, that doesn’t mean that every material is the same. IBC totes are available in polyethylene or stainless steel. Polyethylene tanks feature the benefit of having a lower upfront price, and they also have a smaller maintenance cost. However, stainless steel tanks are more durable, and they can withstand high levels of heat and pressure. They are also environmentally friendly.

How Do I Know if My IBC Tote Is Food-Grade?

The easiest way to know if a container is food-grade is to read the manufacturer’s label. Food-grade containers will always be marked as such. However, if you are buying a used tote, keep in mind that it may not be safe for food just because it is labeled as food-grade. As mentioned, totes used for non-food-related or toxic products such as hazardous waste, chemicals, or pharmaceuticals should not be used for food storage. If you are buying a used tote, be sure that the seller can provide detailed documentation about how the tote was used.

Maintenance of Stainless-Steel Totes

Although IBC totes require little maintenance, you must clean them regularly, especially if using them repeatedly. To clean stainless steel food processing equipment, use industrial-strength CIP cleaning systems whenever possible.

Here at Cedarstone Industry, we not only provide quality stainless-steel food grade IBC totes, but also the materials necessary to keep them clean. No matter how you are using them, your equipment will be ready to help you create the best products possible. Contact us today to learn more.