Our Reviews

5.0 66 reviews

-

Bill Hollman

★★★★★

3 months ago

This is my second purchase from Cedar stone and I’ve been happy with them both times. -

Mario Velotta Jr

★★★★★

2 years ago

I love when I order a part and I receive something that is better than I imagined. Top notch quality here! I build automotive parts with it, but I can count on the … read more fitment to be correct when I open the box to make my products. -

Dennis Estes

★★★★★

3 years ago

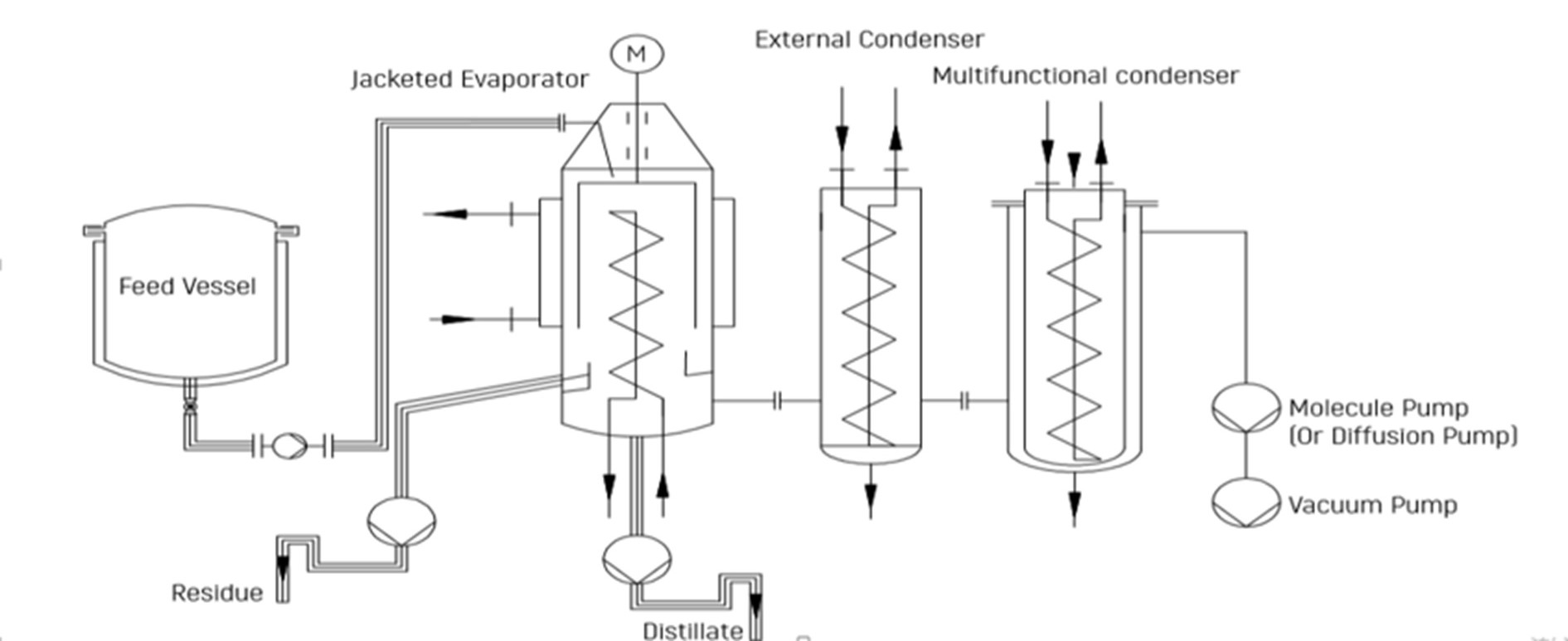

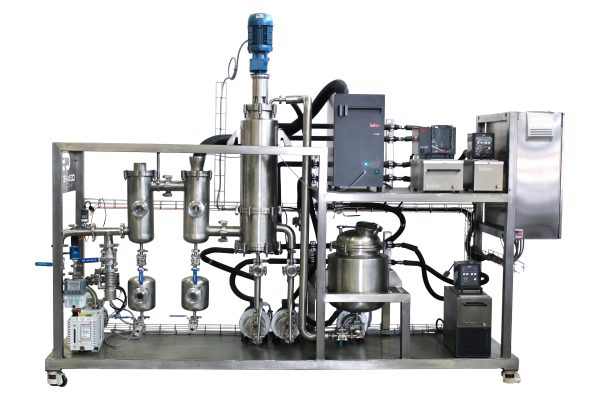

Ask for Carlos Estrada, he's a genius in CBD processing. Their products are like the Rolls Royce of hemp/CBD processing.