What Are Stainless Steel Mixing Tanks and How to Cool Them? Everything You Need to Know

Posted on March 15, 2023 by Cedarstone Industry Team

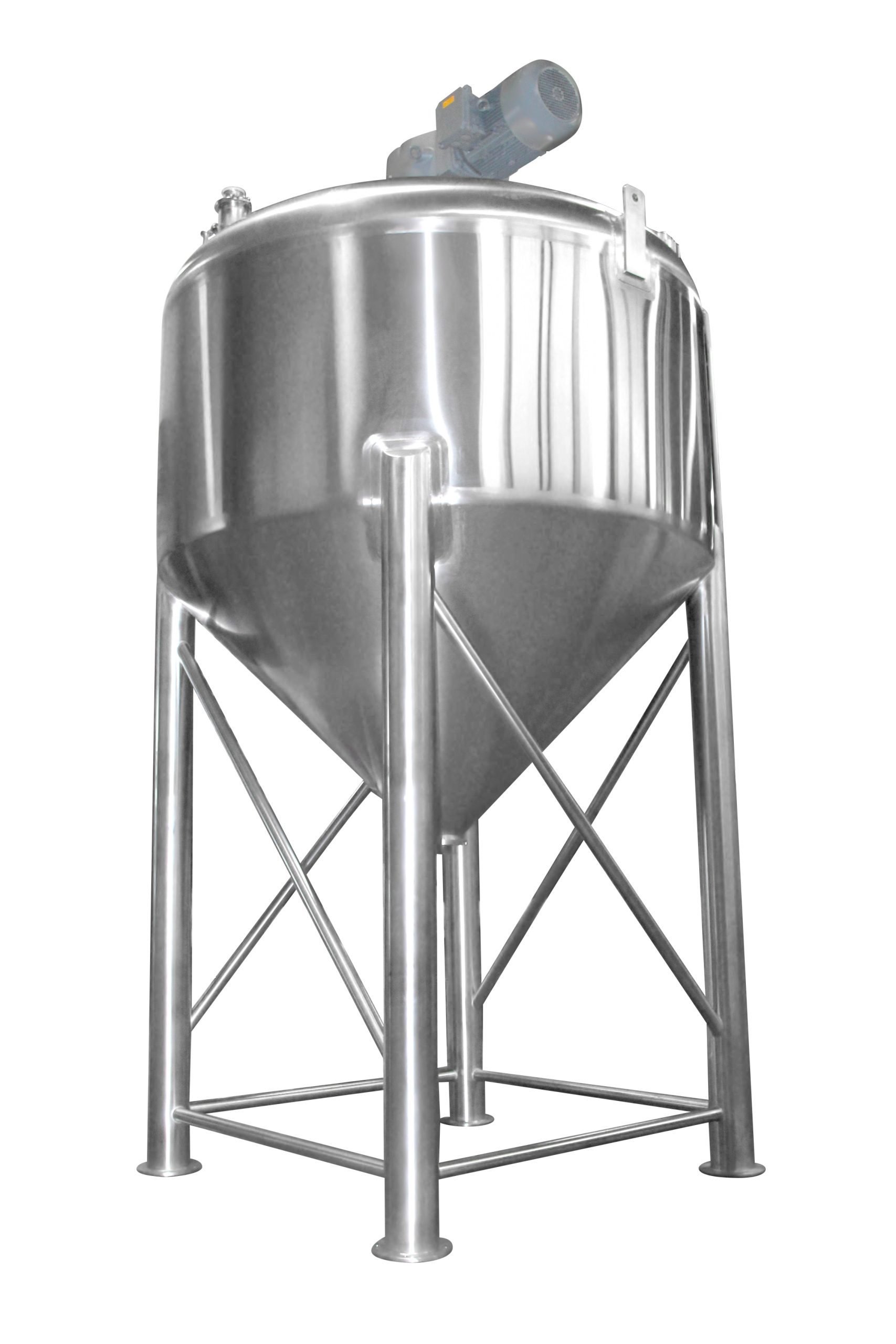

Stainless steel mixing tanks are essential equipment in a variety of industries where different liquids or materials are blended in large quantities. These components are highly durable and corrosion-resistant, which makes them the perfect choice for a range of applications, from food and beverage to pharmaceuticals and chemicals. However, to enjoy all the benefits of stainless steel, first you need to learn how to select perfect components. What is a mixing tank and how to cool it?

What is a mixing tank?

Are you wondering what a mixing tank is? It’s a vessel designed to blend different liquids or materials. It’s usually available in various sizes and shapes. It may also come with an agitator or mixer to facilitate the blending process.

It’s worth mentioning that mixing tanks are commonly used in a range of industries such as food and beverage, pharmaceuticals, chemicals, and cosmetics, among others.

Top benefits of mixing tanks

Stainless steel mixing tanks offer several advantages. Consequently, they’re an ideal choice for various applications. Some of the benefits of using stainless steel mixing tanks include:

- Durability and corrosion resistance – stainless steel is a robust material that can withstand harsh conditions and serve you for longer.

- Hygiene – it’s worth mentioning that stainless steel mixing tanks are made of a non-porous material that is easy to clean and sanitize. Thanks to it, it’s a practical option for the food and beverage industry.

- Versatility – what is a mixing tank? It’s a component that can be used for a range of applications, from blending liquids to mixing solids and semisolids. This makes it useful equipment for all manufacturing companies that care about top quality and efficiency of processes.

- Cost-effectiveness – stainless steel mixing tanks are an affordable option compared to other materials like glass-lined or exotic metals. Want to learn which ones are better: stainless steel vs. plastic tanks? Check our article.

Applications of stainless steel mixing tanks

As you already know, stainless steel mixing tanks stand out thanks to numerous benefits they offer. For this reason, they’re a popular choice among numerous organizations and sectors.

How can they be used? Stainless steel mixing tanks find extensive applications in a range of industries, including:

- Food and beverage industry – mixing tanks are used to blend different ingredients to make products like sauces, dressings, and beverages.

- Pharmaceuticals industry – these pieces of equipment are indispensable in the process of manufacturing drugs and medicines, where precise mixing and blending of different chemicals are required to keep up with the safety and quality standards.

- Chemical industry – it’s another example of industries that benefit from mixing tanks. They’re used to blend different chemicals for making products like detergents, adhesives, and paints.

- Cosmetics industry – mixing tanks can also be helpful in mixing large quantities of different ingredients to manufacture creams, lotions, shampoos and other cosmetics.

Since you know the benefits and applications of this equipment, let’s move on to the main subject of this article – how to cool stainless steel mixing tanks?

How to cool stainless steel mixing tanks?

Cooling stainless steel mixing tanks is an essential process to ensure that the equipment will serve you for longer. What can you use to streamline the process?

- A cooling jacket – it’s a stainless steel shell that surrounds the mixing tank. It allows for the circulation of chilled water or glycol around the vessel, which cools the contents of the tank. Cooling jackets are commonly used in the food and beverage industry.

- An immersion chiller – it’s a coil of stainless steel that is placed inside the mixing tank. It’s connected to a refrigeration unit, which circulates chilled coolant through the coil.

- A cold water bath – use a tank filled with chilled water and place the mixing tank inside to cool its contents.

- Direct injection – it involves injecting chilled water or coolant directly into the mixing tank. This method of cooling stainless steel mixing tanks is particularly popular in the cosmetics industry.

The takeaway

Stainless steel mixing tanks offer several benefits, including durability, corrosion resistance and cost-effectiveness. To achieve the best results, it’s crucial to learn about cooling stainless steel mixing tanks effectively. Some of the methods include cooling jackets, immersion chillers or cold water baths. By following the guidelines described in this article, you can ensure your equipment will serve you for long years to come.